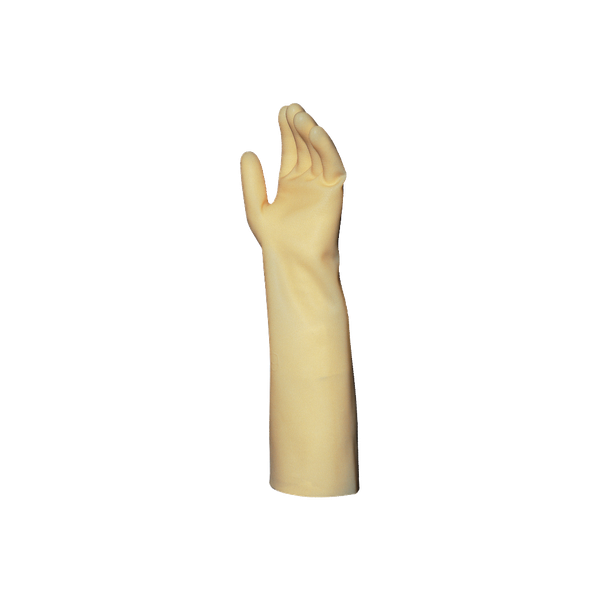

Trionic 521

Unique tri-polymer construction offers 100% comfort for optimal mechanical and chemical resistance

-

CAT. 3

0334

0334

-

1110

1110

-

Specific advantages

Cut protection

Cut protection

- Extensive range adapted to all applications: wide cuff for double-gloving, extended length to protect the forearm

Skin protection

Skin protection

- Excellent resistance and strong chemical protection against a great number of chemical products: exclusive Trionic formula made from a mix of natural latex, neoprene and nitrile

Guaranteed quality

Guaranteed quality

- Manufacturing process ensuring the control of a very low level of contaminants: particulate content, non-volatile residues, extractables => Washed, controlled and packaged in an ISO 5 room / Particle rate measured compatible with the needs of an ISO 4 room

- Silicone free to prevent traces, defects on metal sheet and glass prior to painting

Additional Benefits

Additional Benefits

- Class 10 (ISO 4) Compatible

Product detail

| Material | Natural latex, polychloroprene and nitrile |

|---|---|

| Colour | |

| Interior finish | Chlorinated |

| Exterior finish | Embossed texture |

| Length (cm) | 46 |

| Thickness (mm) | 0.50 |

| Size | 8 9 10 |

| Packaging | 1 pair/bag 72 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 1,1,1-Trichloroethane 99% | 71-55-6 | 7 | 0 | ASTM F739 | NT |

|

| 1,1,1,2,2,3,4,5,5,5-Decafluoropentane 97% | 138495-42-8 | 13 | 1 | ASTM F739 | NT |

|

| 1,1,2-Trichlorotrifluoroethane (Freon TF or Freon 113) 99% | 76-13-1 | 20 | 1 | ASTM F739 | 1 |

|

| 1,2 Dichloroethylene 98% | 156-60-5 | 2 | 0 | ASTM F739 | 2 |

|

| 1,3 Ethoxy propionate (Ethyl 3-ethoxypropionate) 99% | 763-69-9 | >480 | 6 | ASTM F739 | NT |

|

| 2-Butoxyethanol (Butyl Cellusolve) 99% | 111-76-2 | 53 | 2 | ASTM F739 | NT |

|

| 2-Butoxyethylacetate (Butyl cellosolve acetate) 85% | 112-07-2 | 35 | 2 | ASTM F739 | NT |

|

| 2-Ethoxyethanol (Cellosolve) 99% | 110-80-5 | 27 | 1 | ASTM F739 | NT |

|

| 2-Ethoxyethyl acetate (Cellosolve Acetate) 99% | 111-15-9 | 14 | 1 | ASTM F739 | 4 |

|

| 2-Methoxyethanol (Methyl Cellosolve) 99% | 109-86-4 | 40 | 2 | ASTM F739 | NT |

|

| 2-Methoxyethanol Acetate (Methyl cellosolve acetate) 98% | 110-49-6 | 27 | 1 | ASTM F739 | NT |

|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | 38 | 2 | ASTM F739 | 4 |

|

| 4,4 - diamino diphenylsulfone 97% | 80-008-0 | >480 | 6 | ASTM F739 | NT |

|

| 4,4'-Methylenedianiline (MDA) 15% and 15% Methanol mixture | 101-77-9 | 19 | 1 | ASTM F739 | NT |

|

| 4,4'-Methylenedianiline (MDA) 15% in Toluene mixture | 101-77-9 | <15 | 1 | ASTM F739 | NT |

|

| Acetic acid 99% | 64-19-7 | 32 | 2 | ASTM F739 | 4 |

|

| Acetone 99% | 67-64-1 | 6 | 0 | ASTM F739 | 4 |

|

| Aluminum Etch mixture | NA | >960 | 6 | ASTM F739 | 4 |

|

| Aluminum Oxide mixture | NA | 55 | 2 | ASTM F739 | NT |

|

| Ammonium Fluoride 40% | 12125-01-8 | >480 | 6 | ASTM F739 | NT |

|

| Ammonium Fluoride 79% | 12125-01-8 | >480 | 6 | ASTM F739 | NT |

|

| Ammonium hydroxide solution 29% | 1336-21-6 | 36 | 2 | ASTM F739 | 4 |

|

| Baker PRS-1000 mixture | NA | <20 | 1 | ASTM F739 | NT |

|

| Baker PRS-2000 mixture | NA | 130 | 4 | ASTM F739 | NT |

|

| Baker PRS-3000 mixture | NA | >480 | 6 | ASTM F739 | NT |

|

| Benzene 99% | 71-43-2 | 4 | 0 | ASTM F739 | 1 |

|

| Buffered Oxide Etch mixture | NA | >480 | 6 | ASTM F739 | 4 |

|

| Butyl Acetate 99% | 123-86-4 | 7 | 0 | ASTM F739 | 4 |

|

| Chromic Acid 50% | 7738-94-5 | 60 | 2 | ASTM F739 | NT |

|

| Cyclohexanone 99% | 108-94-1 | 23 | 1 | ASTM F739 | 1 |

|

| Cyclopentanone 99% | 120-92-3 | 11 | 1 | ASTM F739 | NT |

|

| Dichloromethane (Methylene Chloride) 99% | 75-09-2 | >4 | 0 | ASTM F739 | NT |

|

| Dichromate cleaning solution mixture | NA | >480 | 6 | ASTM F739 | 4 |

|

| Diethylamine 98% | 109-89-7 | 4 | 0 | ASTM F739 | NT |

|

| Diglycidal ether of bisphenol 100% | 25068-38-6 | >480 | 6 | ASTM F739 | NT |

|

| Dimethylamine 35% | 124-40-3 | 53 | 2 | ASTM F739 | NT |

|

| Dimethylformamide 99% | 68-12-2 | 8 | 0 | ASTM F739 | NT |

|

| Dimethylsulfoxide 99% | 67-68-5 | 181 | 4 | ASTM F739 | 4 |

|

| Epichlorohydrin 99% | 106-89-8 | 4 | 0 | ASTM F739 | NT |

|

| Ethanol 95% | 64-17-5 | 21 | 1 | ASTM F739 | NT |

|

| Ethyl lactate 95% | 97-64-3 | 29 | 1 | ASTM F739 | NT |

|

| Ethylene glycol 99% | 107-21-1 | >480 | 6 | ASTM F739 | 4 |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Hexamethyldisilazane (HMDS) 98% | 999-97-3 | 18 | 1 | ASTM F739 | 1 |

|

| Hydrochloric acid 10% | 7647-01-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Hydrochloric acid 37% | 7647-01-0 | 454 | 5 | ASTM F739 | 4 |

|

| Hydrofluoric Acid 10% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Hydrofluoric Acid 40% | 7664-39-3 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Hydrofluoric Acid 49% | 7664-39-3 | 390 | 5 | ASTM F739 | NT |

|

| Hydrogen peroxide 30% | 7722-84-1 | >960 | 6 | ASTM F739 | 4 |

|

| Hydrotreated Light Naphthenic Distillate mixture | 64742-53-6 | 161 | 4 | ASTM F739 | 2 |

|

| Kerosene mixture | 8008-20-6 | 26 | 1 | ASTM F739 | 1 |

|

| KOH Etch mixture | NA | 278 | 5 | ASTM F739 | 4 |

|

| KTI Pad Etch mixture | NA | >480 | 6 | ASTM F739 | NT |

|

| KTI Silicon Etch mixture | NA | >480 | 6 | ASTM F739 | NT |

|

| Methanol 85% | 67-56-1 | 19 | 1 | ASTM F739 | 4 |

|

| Methyl Amyl Ketone 98% | 110-43-0 | 8 | 0 | ASTM F739 | 1 |

|

| Methyl Ethyl Ketone (2-Butanone) 99% | 78-93-3 | 4 | 0 | ASTM F739 | 3 |

|

| Methyl-3-methoxypropionate 100% | 3852-09-3 | 11 | 1 | ASTM F739 | 3 |

|

| n-hexane 95% | 110-54-3 | 3 | 0 | ASTM F739 | 1 |

|

| N-methyl-2-Pyrrolidone 99% | 872-50-4 | 50 | 2 | ASTM F739 | 4 |

|

| N-N dimethyl acetamide 99% | 127-19-5 | 47 | 2 | ASTM F739 | NT |

|

| Naphtha VM&P mixture | 8032-32-4 | 2 | 0 | ASTM F739 | 1 |

|

| Nitric acid 10% | 7697-37-2 | >840 | 6 | ASTM F739 | 4 |

|

| Nitric acid 20% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 40% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 68% | 7697-37-2 | 299 | 5 | EN 374-3:2003 | 4 |

|

| Nitric acid 70% | 7697-37-2 | 307 | 5 | ASTM F739 | 4 |

|

| Nitric acid 90% | 7697-37-2 | 7 | 0 | ASTM F739 | NT |

|

| Nitrohydrochloric acid (Aqua Regia) mixture | 8007-56-5 | >480 | 6 | ASTM F739 | NT |

|

| Phenol 85% | 108-95-2 | 102 | 3 | ASTM F739 | 4 |

|

| Phosphoric acid 75% | 7664-38-2 | >480 | 6 | ASTM F739 | 4 |

|

| Phosphoric acid 85% | 7664-38-2 | >480 | 6 | ASTM F739 | 4 |

|

| Phosphorus oxychloride 99% | 10025-87-3 | <15 | 1 | ASTM F739 | NT |

|

| Polyethylene glycol octylphenyl ether 100% | 9002-93-1 | >480 | 6 | ASTM F739 | NT |

|

| Potassium Hydroxide 50% | 1310-58-3 | >480 | 6 | ASTM F739 | 4 |

|

| Potassium Hydroxide Etch mixture | NA | 24 | 1 | ASTM F739 | NT |

|

| Propylene Glycol 99% | 57-55-6 | >480 | 6 | ASTM F739 | 4 |

|

| Propylene Glycol Methyl Ethyl Acetate (PGMEA) 99% | 108-65-6 | 47 | 2 | ASTM F739 | 3 |

|

| Propylene Glycol Monomethyl Ether 99% | 107-98-2 | 26 | 1 | ASTM F739 | 4 |

|

| Silicon tetrachloride 100% | 10026-04-7 | <15 | 1 | ASTM F739 | NT |

|

| Slope Etch mixture | NA | 260 | 5 | ASTM F739 | 4 |

|

| Sodium hydroxide 20% | 1310-73-2 | >780 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >780 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >780 | 6 | ASTM F739 | 4 |

|

| Sulfuric acid 10% | 7664-93-9 | >900 | 6 | ASTM F739 | 4 |

|

| Sulfuric acid 96% | 7664-93-9 | 102 | 3 | ASTM F739 | 3 |

|

| Tetrachloroethylene (Perchloroethylene) 99% | 127-18-4 | 4 | 0 | ASTM F739 | 1 |

|

| Tetraethyl Orthosilicate 100% | 78-10-4 | 25 | 1 | ASTM F739 | 1 |

|

| Tetramethyl Ammonium Hydroxide 25% | 75-59-2 | >480 | 6 | ASTM F739 | 4 |

|

| Thionylchloride 99% | 7719-09-7 | <15 | 1 | ASTM F739 | NT |

|

| Toluene 49% Methyl Isobutyl Ketone 34.5% Methyl Ethyl Ketone 16.5% mixture | NA | 1 | 0 | EN 374-3:2003 | NT |

|

| Toluene Diisocyanate (TDI) 80% | 584-84-9 | 27 | 1 | ASTM F739 | NT |

|

| Trimethylphosphite 97% | 121-45-9 | 10 | 0 | ASTM F739 | NT |

|

| Unleaded gasoline mixture | 8006-61-9 | 4 | 0 | ASTM F739 | 1 |

|

| Xylene 99% | 1330-20-7 | 4 | 0 | ASTM F739 | 1 |

|

*not normalized result

More gloves

AdvanTech 522

A tripolymer exclusive that offers 100% comfort for optimal mechanical and chemical resistance

Trionic O-240

A tripolymer exclusive that offers 100% comfort for optimal mechanical and chemical resistance

RollPruf 0726

Triple polymer provides durability and strength with color band at rolled cuff edge to identify size.