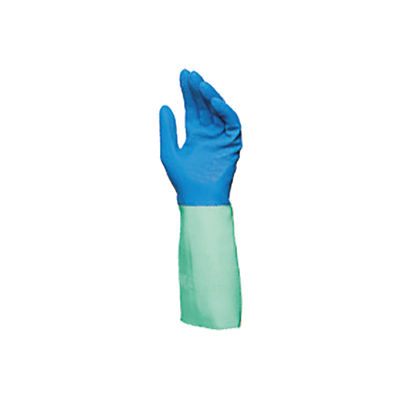

StanSolv AF15

Good sensitivity for standard chemical protection

-

CAT. 3

0334

0334

-

4101

4101

- JKL

-

Specific advantages

Comfort

Comfort

- Excellent dexterity, for handling small objects

- Flock lining provides comfort and absorbs perspiration

Productivity

Productivity

- Good grip on slippery objects, due to the embossed texture

Applications

Mechanical industry

- Assembly of small, oil and grease free parts

- Chemical treatment of metals

- Maintenance in wet environments (water, oil, greases, hydrocarbons)

Chemical industry

- Cleaning tanks

- Handling and transporting chemicals (solvents)

Product detail

| Material | Nitrile |

|---|---|

| Colour | green |

| Interior finish | Flocked |

| Exterior finish | Embossed texture |

| Length (cm) | 31 |

| Thickness (mm) | .38 |

| Size | 7 8 9 10 11 |

| Packaging | 12 pairs/bag 72 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| Carbon disulfide 99% | 75-15-0 | 4 | 0 | ASTM F739 | NT |

|

| Diethylamine 98% | 109-89-7 | 16 | 1 | ASTM F739 | NT |

|

| Dimethylformamide 99% | 68-12-2 | 11 | 1 | ASTM F739 | 1 |

|

| Methanol 99% | 67-56-1 | 24 | 1 | ASTM F739 | 4 |

|

| n-Heptane 99% | 142-82-5 | >480 | 6 | EN 374-3:2003 | NT |

|

| n-hexane 95% | 110-54-3 | >480 | 6 | ASTM F739 | 4 |

|

| Nitrobenzene 99% | 98-95-3 | 20 | 1 | ASTM F739 | NT |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Sulfuric acid 96% | 7664-93-9 | 60 | 2 | ASTM F739 | 1 |

|

| Tetrachloroethylene (Perchloroethylene) 99% | 127-18-4 | 52 | 2 | ASTM F739 | NT |

|

| Tetrahydrofurane 99% | 109-99-9 | 4 | 0 | ASTM F739 | NT |

|

| Toluene 99% | 108-88-3 | 9 | 0 | ASTM F739 | NT |

|

*not normalized result

More gloves

StanSolv A14

Unique Z-pattern grip provide secure handling of hard-to-grasp items