FluoTech 468

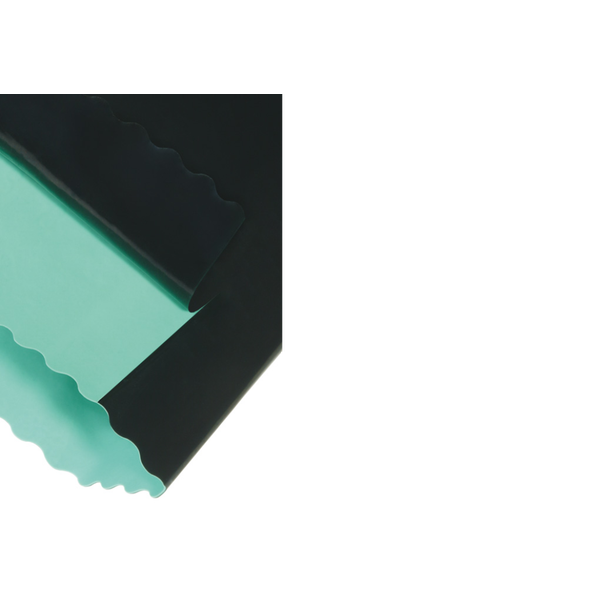

Tactile sensitivity with wear-indicator

-

CAT. 3

0334

0334

-

3102X

3102X

-

Type A

ADEFGJLMNO

ADEFGJLMNO

-

Specific advantages

Comfort

Comfort

- Excellent flexibility and thickness optimization, due to the Mapa multi-layer technology: good dexterity and comfort

Durability

Durability

- Nitrile inner layer: excellent mechanical resistance and a longer service life

Guaranteed quality

Guaranteed quality

- Silicone free to prevent traces, defects on metal sheet and glass prior to painting

Practical

Practical

- Green inner layer: wear-indicator for greater user safety

Applications

Mechanical industry

- Metal degreasing and etching

Chemical industry

- Chemical treatments (solvents)

- Galvanoplasty

- Handling and transporting chemicals (solvents)

- Manufacturing paints and varnishes

- Resin and adhesive manufacturing

Other industries

- Petrochemical refining

- Printing

- Site pollution control

Product detail

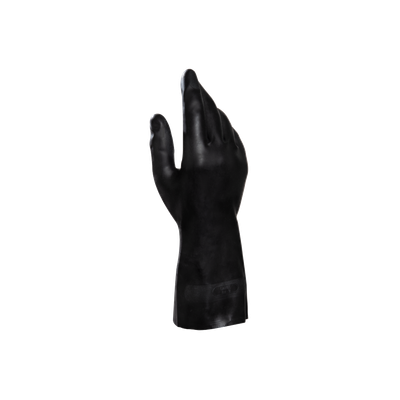

| Material | Fluoroelastomer |

|---|---|

| Colour | black |

| Interior finish | Chlorinated |

| Exterior finish | Smooth |

| Length (cm) | 30 |

| Thickness (mm) | 0.51 |

| Size | 8 9 10 |

| Packaging | 1 pair/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

Used for high chemical exposure or chemical immersion, limited to breakthrough time based on a working day.

Used for repeated chemical contact, limited to total chemical exposure i.e. : accumulative breakthrough time based on a working day.

Splash protection only, on chemical exposure the gloves should be discarded and new gloves worn as soon as possible.

Not recommended, these gloves are deemed unsuitable for work with this chemical.

NT: Not tested

NA: "Not applicable" because not fully tested (only degradation OR permeation results)

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 1,1,1-Trichloroethane 99% | 71-55-6 | >480 | 6 | ASTM F739 | NT |

|

| 1,2 - dichloroethane 99% | 107-06-2 | >480 | 6 | ASTM F739 | 4 |

|

| 2,2,2-Trifluoroethanol 99% | 75-89-8 | >480 | 6 | ASTM F739 | NT |

|

| Acetic acid 99% | 64-19-7 | 142 | 4 | EN 16523-1:2015 | 2 |

|

| Acetone 99% | 67-64-1 | 5 | 0 | ASTM F739 | 1 |

|

| Acetonitrile 99% | 75-05-8 | 16 | 1 | ASTM F739 | 1 |

|

| Acrylic acid 95% | 79-10-7 | >480 | 6 | ASTM F739 | 4 |

|

| Acrylic acid 99% | 79-10-7 | >480 | 6 | ASTM F739 | 4 |

|

| Ammonium hydroxide solution 25% | 1336-21-6 | >480 | 6 | EN 16523-1:2015 | 3 |

|

| Benzene 99% | 71-43-2 | >480 | 6 | ASTM F739 | 4 |

|

| Butyl Acetate 99% | 123-86-4 | 72 | 3 | ASTM F739 | 1 |

|

| Carbon disulfide 99% | 75-15-0 | >480 | 6 | ASTM F739 | 4 |

|

| Carbon Tetrachloride 99% | 56-23-5 | >480 | 6 | ASTM F739 | NT |

|

| Chlorobenzene 99% | 108-90-7 | >480 | 6 | ASTM F739 | 4 |

|

| Chloroform 99% | 67-66-3 | >480 | 6 | ASTM F739 | 4 |

|

| Cyclohexane 99% | 110-82-7 | >480 | 6 | ASTM F739 | 4 |

|

| Dichloromethane (Methylene Chloride) 99% | 75-09-2 | 64 | 3 | ASTM F739 | 1 |

|

| Diethylamine 98% | 109-89-7 | 90 | 3 | ASTM F739 | 1 |

|

| Dimethylformamide 99% | 68-12-2 | 41 | 2 | ASTM F739 | 1 |

|

| Ether (Diethyl Ether) 99% | 60-29-7 | 72 | 3 | ASTM F739 | 3 |

|

| Ethyl acetate 99% | 141-78-6 | 14 | 1 | ASTM F739 | 1 |

|

| Ethyl benzene 99% | 100-41-4 | >480 | 6 | ASTM F739 | 4 |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Furfural 99% | 98-01-1 | 113 | 3 | ASTM F739 | NT |

|

| Hydrochloric acid 10% | 7647-01-0 | >480 | 6 | ASTM F739 | NT |

|

| Hydrochloric acid 35% | 7647-01-0 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Hydrochloric acid 37% | 7647-01-0 | >480 | 6 | ASTM F739 | NT |

|

| Hydrogen peroxide 30% | 7722-84-1 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Iodomethane (Methyl Iodide) 99% | 74-88-4 | >480 | 6 | ASTM F739 | NT |

|

| Methanol 99% | 67-56-1 | 108 | 3 | ASTM F739 | 4 |

|

| Methyl Acrylate 99% | 96-33-3 | 26 | 1 | ASTM F739 | NT |

|

| Methyl Ethyl Ketone (2-Butanone) 99% | 78-93-3 | 10 | 1 | ASTM F739 | 1 |

|

| n-Heptane 99% | 142-82-5 | >480 | 6 | ASTM F739 | 4 |

|

| n-hexane 95% | 110-54-3 | >480 | 6 | ASTM F739 | 4 |

|

| N-N dimethyl acetamide 99% | 127-19-5 | 33 | 1 | ASTM F739 | 1 |

|

| Nitric acid 10% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 20% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 40% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 50% | 7697-37-2 | >480 | 6 | ASTM F739 | 4 |

|

| Nitric acid 65% | 7697-37-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Pentane 99% | 109-66-0 | >480 | 6 | ASTM F739 | 4 |

|

| Phenol 85% | 108-95-2 | >480 | 6 | ASTM F739 | NT |

|

| Phosphoric acid 75% | 7664-38-2 | >480 | 6 | ASTM F739 | NT |

|

| Phosphoric acid 85% | 7664-38-2 | >480 | 6 | ASTM F739 | NT |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | ASTM F739 | 4 |

|

| Styrene 99% | 100-42-5 | >480 | 6 | ASTM F739 | 4 |

|

| Sulfuric acid 10% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 40% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 50% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sulfuric acid 96% | 7664-93-9 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Tetrachloroethylene (Perchloroethylene) 99% | 127-18-4 | >480 | 6 | ASTM F739 | NT |

|

| Tetrahydrofurane 99% | 109-99-9 | 12 | 1 | ASTM F739 | 1 |

|

| Toluene 99% | 108-88-3 | >480 | 6 | ASTM F739 | 4 |

|

| Trichloroethylene 99% | 79-01-6 | >480 | 6 | ASTM F739 | NT |

|

| Vinyl acetate 99% | 108-05-4 | 29 | 1 | ASTM F739 | NT |

|

| Xylene 99% | 1330-20-7 | >480 | 6 | ASTM F739 | 4 |

|

*not normalized result