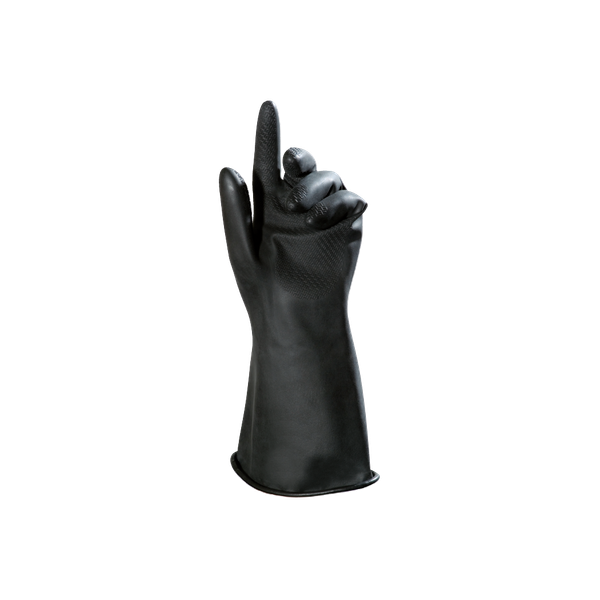

Butoflex 651

Ultimate specific chemical resistance

-

CAT. 3

0334

0334

-

0010X

0010X

-

Type A

ABCILMNOS

ABCILMNOS

-

-

Specific advantages

Protection of electronic device from ElectroStatic Discharge (ESD)

Protection of electronic device from ElectroStatic Discharge (ESD)

- In compliance with the requirement of the norm EN 16350, standard for protective gloves - Electrostatic properties : <1.0 10E5

Comfort

Comfort

- Unrivalled flexibility and dexterity

Skin protection

Skin protection

- Ultimate specific chemical resistance, for very corrosive acids, ketones, esters and amine derivatives

Guaranteed quality

Guaranteed quality

- Silicone free to prevent traces, defects on metal sheet and glass prior to painting

Specific features

The only Butyl glove on the market with an exclusive embossed exterior finish, meaning slippery objects can be handled without risk.

Applications

Mechanical industry

- Metal treatment and degreasing

Chemical industry

- Formulating paints, varnishes, resins and inks

- Handling and repackaging chemicals

- Sampling chemicals

Cosmetics and Pharmaceutical industry

- Handling in laboratories

Product detail

| Material | Butyl |

|---|---|

| Colour | black |

| Interior finish | Smooth |

| Exterior finish | Embossed texture |

| Length (cm) | 37 |

| Thickness (mm) | .56 |

| Size | 7 8 9 10 |

| Packaging | 1 pair/bag 6 pairs/carton |

Chemical chart

OVERALL CHEMICAL PROTECTION RATING

Protection rating is determined by taking into account the effects of both permeation and degradation in an attempt to provide users with an overall protection guideline when using our glove products against specific chemicals.

Meaning of the colours :

The chemical test data and overall chemical protection rating should not be used as the absolute basis for glove selection. Actual in-use conditions may vary glove performance from the controlled conditions of laboratory tests. Factors other than chemical contact time

| Chemical Product | CAS # | Breakthrough time (minutes) |

Permeation level |

Standard | Degradation level |

Rating |

|---|---|---|---|---|---|---|

| 2-Propanol (Isopropanol) 99% | 67-63-0 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Acetic acid 10% | 64-19-7 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Acetic acid 50% | 64-19-7 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Acetic acid 99% | 64-19-7 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Acetone 99% | 67-64-1 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Acetonitrile 99% | 75-05-8 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Acrylic acid 95% | 79-10-7 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Acrylic acid 99% | 79-10-7 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Ammonia 99% | 7664-41-7 | >480 | 6 | EN 374-3:2003 | NT |

|

| Ammonium hydroxide solution 25% | 1336-21-6 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Carbon disulfide 99% | 75-15-0 | 1 | 0 | EN 374-3:2003 | 4 |

|

| Chlorine 100% | 7782-50-5 | >480 | 6 | EN 374-3:2003 | NT |

|

| Dichloromethane (Methylene Chloride) 99% | 75-09-2 | 12 | 1 | EN 374-3:2003 | 2 |

|

| Diethylamine 98% | 109-89-7 | 11 | 1 | EN 374-3:2003 | 2 |

|

| Dimethylformamide 99% | 68-12-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Ethanol 95% | 64-17-5 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Ethyl acetate 99% | 141-78-6 | 158 | 4 | EN 16523-1:2015 | 4 |

|

| Ethyl methacrylate 99% | 97-63-2 | 81 | 3 | ASTM F739 | NT |

|

| Formaldehyde 37% | 50-00-0 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Hydrofluoric Acid 10% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | NT |

|

| Hydrofluoric Acid 40% | 7664-39-3 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Hydrofluoric Acid 49% | 7664-39-3 | >480 | 6 | EN 374-3:2003 | NT |

|

| Hydrogen chloride 99% | 7647-01-0 | >480 | 6 | EN 374-3:2003 | NT |

|

| Hydrogen fluoride Anhydrous 100% Liq. | 7664-39-3 | 4 | 0 | EN 16523-1:2015 | NT |

|

| Hydrogen peroxide 30% | 7722-84-1 | >480 | 6 | EN 16523-1:2015 | NT |

|

| Isobutyl methacrylate 97% | 97-86-9 | 105 | 3 | ASTM F739 | NT |

|

| Methanol 85% | 67-56-1 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Methanol 99% | 67-56-1 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Methyl acetate 99% | 79-20-9 | 273 | 4 | ASTM F739 | NT |

|

| Methyl Ethyl Ketone (2-Butanone) 99% | 78-93-3 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Methyl methacrylate 99% | 80-62-6 | 89 | 3 | EN 374-3:2003 | 4 |

|

| n-butyl methacrylate 99% | 97-88-1 | 90 | 3 | ASTM F739 | NT |

|

| n-Heptane 99% | 142-82-5 | 15 | 1 | EN 374-3:2003 | 1 |

|

| N-N dimethyl acetamide 30% | 127-19-5 | >480 | 6 | ASTM F739 | NT |

|

| N-N dimethyl acetamide 99% | 127-19-5 | >480 | 6 | ASTM F739 | NT |

|

| Naphtha, Hydrotreated Heavy mixture | 64742-48-9 | 45 | 2 | EN 374-3:2003 | 2 |

|

| Nitric acid 10% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 20% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 40% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 50% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Nitric acid 65% | 7697-37-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Nitric acid 68% | 7697-37-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Phosphoric acid 75% | 7664-38-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Phosphoric acid 85% | 7664-38-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | 4 |

|

| Styrene 99% | 100-42-5 | 19 | 1 | EN 374-3:2003 | 2 |

|

| Sulfuric acid 10% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 40% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 50% | 7664-93-9 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 96% | 7664-93-9 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Tetrahydrofurane 99% | 109-99-9 | 13 | 1 | EN 374-3:2003 | 1 |

|

| Toluene 99% | 108-88-3 | 7 | 0 | EN 374-3:2003 | 1 |

|

| Vinyl acetate 99% | 108-05-4 | 212 | 4 | ASTM F739 | NT |

|

| Xylene 99% | 1330-20-7 | 10 | 0 | EN 374-3:2003 | 1 |

|

*not normalized result

More gloves

Pylox V-20

Hand-specific, curved-finger design for low hand fatigue, excellent fit.